We manufacture Radiators with width of

Along with 3.5 inches and 4.5 inches single ERW header pipe with welding of fins from outside as per the international standards.

The Radiators are manufactured with both 1mm CRCA sheet and 1.2 mm CRCA sheet as required and centre distance varying from 600 mm to 4000 mm.

The number of fins pertaining to each radiator is according to customer specification upto 40 numbers.

The different types of Radiators are as follows:

Flanged type Radiator

PE Tarang majorly deals in Transformer Radiators and our Flanged type radiators are used for both Power and Distribution Transformers. These are most commonly used as they are attached to the Transformer tanks and can be detached if needed.These radiators are properly painted with Epoxy & P.U Top-coat painting.

Hot Dip Galvanized Radiator

Galvanizing is a way of defending a steel surface from corrosion by delivering a surface coat of Zinc. The process is carried out by dipping the radiator in molten zinc bath which is upheld at a temperature of about 450 degrees. The Hot Dip Galvanizing is done in accordance with BS 729 and IS 2629 up to a thickness of minimum 85 microns.

Stainless Steel Radiator

Radiators in this case are manufactured with Stainless steel (SS304, SS316 and SS316L).

These radiators are manufactured with both 1mm CRCA sheet and 1.2 mm CRCA sheet as required and centre distance varying from 600 mm to 4000 mm.

Stainless steel radiators can be offered with and without paint.

Gooseneck type Radiator

Goose neck type of radiators are accessible with bend pipes at space restraint areas and can be made accessible with or without inserted sections provisional on the heat dissipation and oil quantity needed. It is possible to have a goose neck for offset type radiators also.

Off-set type Radiator

P.E.Tarang is the leading Off Set Transformer Radiator Manufacturer and supplier in Hyderabad and Nagpur. Off-set type of radiators would be manufactured with right off-set or left off-set at a distance of 130 mm or 180 mm as indicated by the valuable customers and Off-set is applicable for both welded type and flanged type radiators. Being the leading Transformer Radiator Manufacturer our Off Set Radiators are presented with all associated Accessories & necessary painting system. These radiators are properly painted with Epoxy & P.U Top-coat painting.

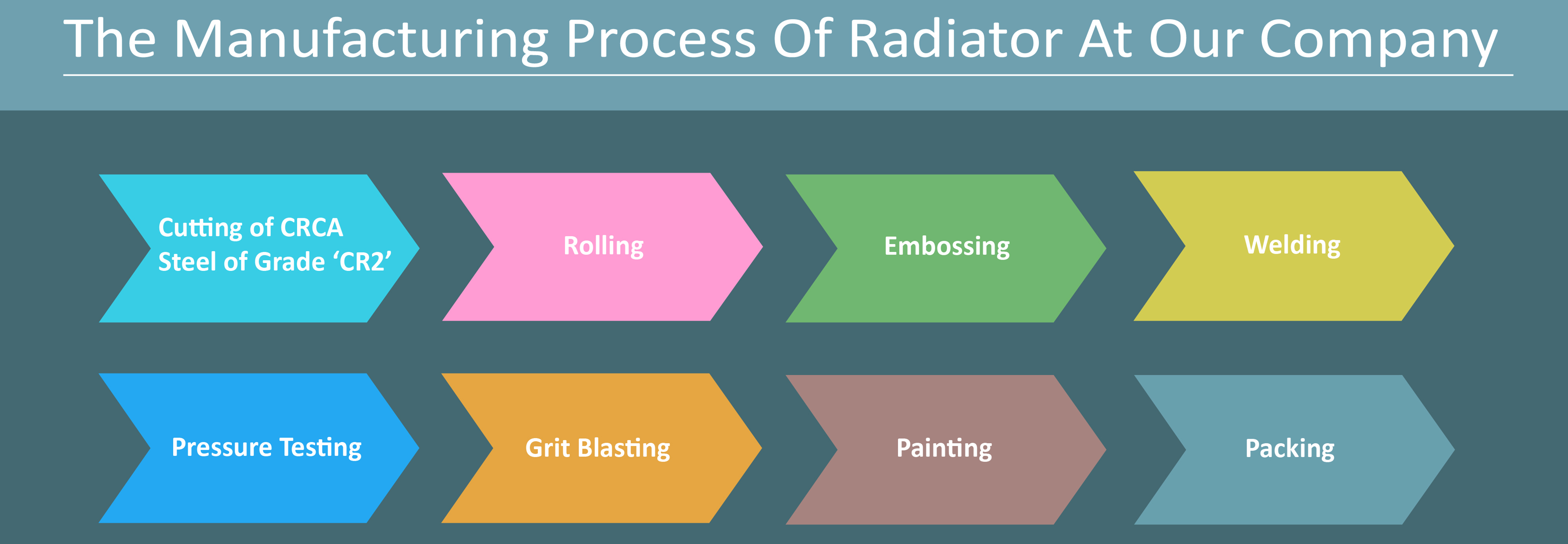

The process at our group companies begin with cutting of CRCA steel of grade ‘CR2’ and carried forward with rolling, embossing, welding, pressure testing, grit blasting and finally painting. Being an ISO 9001:2008 organization, we adhere to quality at each stage with regular in-process checks.

Our 24-flute profile radiator is specially designed for higher surface area and less oil content as per international standards.

The process of Grit Blasting conforms to Swedish standard SA 2.5

Further, each radiator undergoes internal coating with Phenolic Varnish or Interprime 741/Ching RD124.

Our process conforms to IEEMA 9-1990, DIN 42559 and En 50216 standards unless specified by the customers.

The general painting scheme is of the following types:

EN01

2 coats of Enamel primer followed by 1 coat of Enamel finish to the required shade as per standards: IS5, BS, RAL, etc. to 80 microns DFT.

EP01

2 coats of Epoxy primer followed by 1 coat of Epoxy finish to the required shade as per standards: IS5, BS, RAL, etc. to 80 microns DFT.

PU01

2 coats of Epoxy primer followed by 1 coat of Polyurethane finish to the required shade as per standards: IS5, BS, RAL, etc. to 80 microns DFT.

Note: DFT (Dry Film Thickness) may vary from 80-350 microns as required by customer.

In addition to the above mentioned, the paint scheme may change depending on the customer requirement (like inclusion of an MIO-Micaceous Iron Oxide paint).

The radiators are then packed and despatched in wooden crates with proper packing labels. It is a full-box packing in case of exports.